AP Racing by Essex Radi-CAL Competition Brake Kit (Front 9668/390mm)-Gen.6 Camaro, Cadillac ATS-V & CTS-V (V3)

$5,999.00

4 in stock

Description

Part #: 13.01.10112

Brand: AP Racing

Complete front Essex Designed AP Racing Radi-CAL Competition Brake Kit for

- Saves 20 unsprung lbs. from nose vs. OEM brakes

- Fits behind OEM 1LE 20″ without a spacer

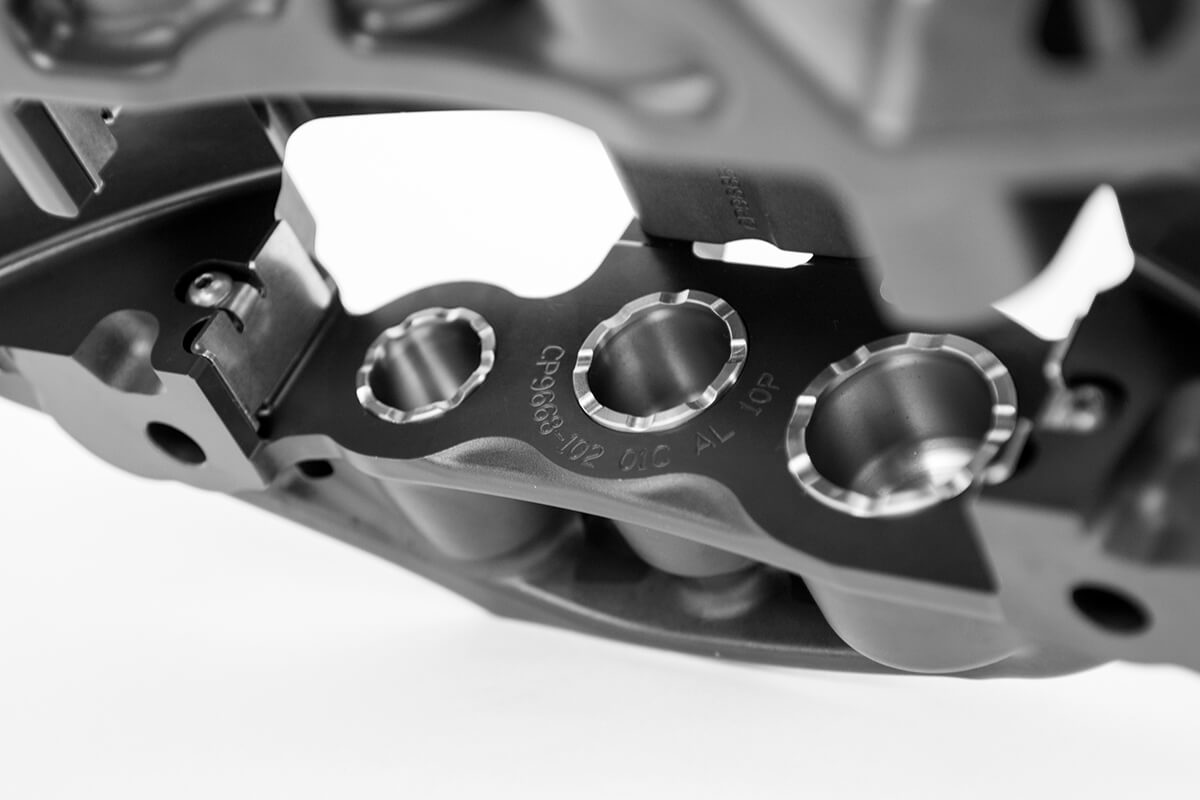

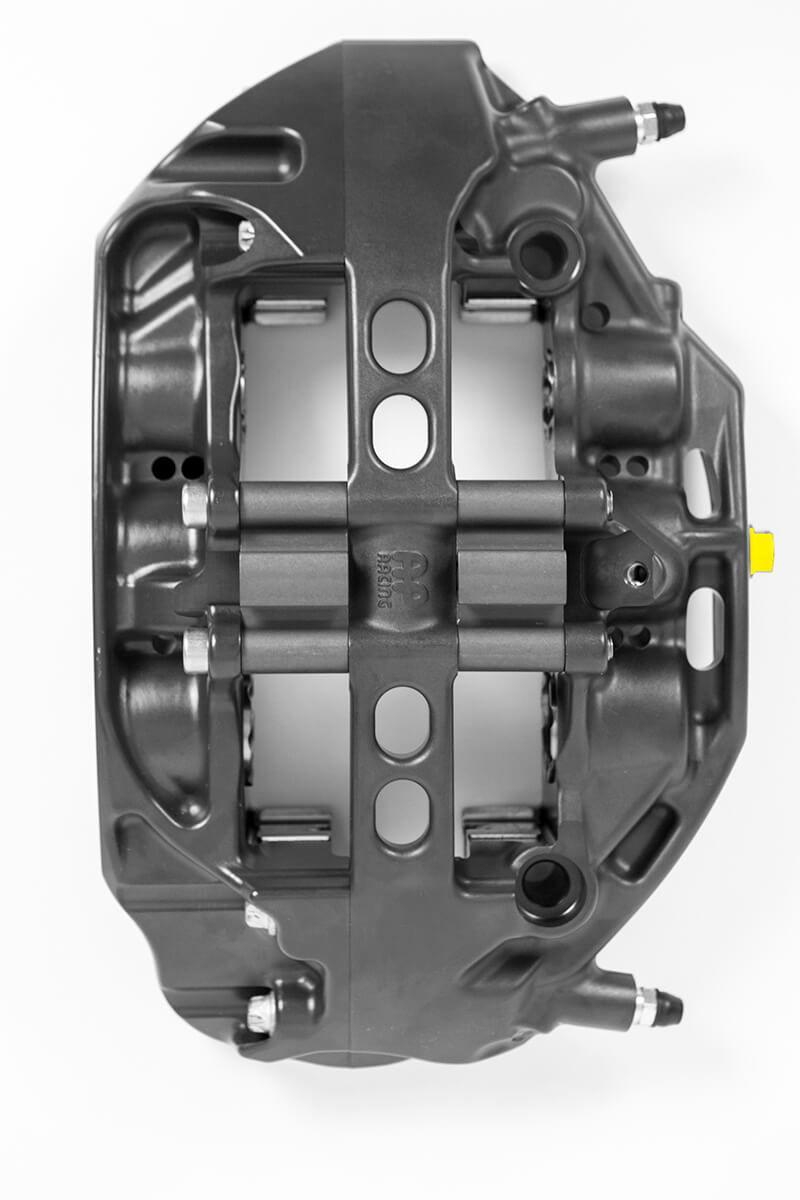

- Features AP Racing CP9668 Radi-CAL Pro5000R six piston calipers

- 390x34mm, 84 vane AP Racing disc

- Every component designed to resist the heat of extended track sessions

- Pistons sized properly to allow for seamless integration with OEM master cylinder and ABS system

- Designed to work with OEM rear brakes or our AP Racing rear BBK

Fits: Front (2020 Chevrolet Camaro ZL1-1LE)

Radi-CAL= Ultra-lightweight, Compact Design with High Airflow

“Radi-CAL” is a blanket term used to describe AP Racing’s patented asymmetrical brake caliper design. Radi-Cal technology is grounded in Computer Aided Design (CAD) and Finite Element Analysis (FEA), and allows for organic, alien-looking designs that are a radical departure from conventional caliper designs of the past. Radi-CAL’s are widely considered the pinnacle of current brake caliper technology. Since their inception in 2007, these revolutionary calipers have amassed a lengthy string of race victories at all levels of professional motorsport, while redefining brake performance expectations.

The key benefits of the Radi-CAL design:

- Massive Stiffness Increase– A 30+ % increase in both static and dynamic stiffness vs. conventional calipers allows for far less deflection under load, which means superior pedal feel & modulation, more even pad wear, and longer caliper service life.

- Considerable Mass Reduction– Removing all extraneous caliper mass lowers the caliper weight, despite the huge stiffness increases.

- Optimized Airflow– Air moves around and through the caliper more efficiently, providing superior heat evacuation and cooling.

- Efficient Packaging– The asymmetric caliper profile and internal fluid porting allows the caliper to fit into tighter spaces.

It has taken eight years, numerous generations of the design concept, and advancements in manufacturing techniques, but the Radi-CAL has finally evolved into a viable solution for racers and enthusiasts of all levels and budgets. While many products are supposedly born in racing, there can be no doubt about the Pro5000R pedigree. These calipers are direct descendants of the current crop of F1 and Sprint Cup calipers. They don’t look ordinary, because they’re not ordinary. They’re the epitome of pure racing design: elegant, sparse, and brutally effective. And while they embody and employ the Radi-CAL design philosophy of the past, they also add some outstanding new features that enhance their practicality, convenience, and appeal. Quite simply, they are the lightest, stiffest, and most technologically advanced brake calipers that have ever been within the average enthusiast’s grasp.

These intricate calipers have traditionally been machined from proprietary aluminum alloy billets. As one can imagine, machining away all of that material to achieve the final form is both time-consuming and costly. As a result, the price of these calipers has historically been prohibitive for the average club racer, time-trialer, or HPDE participant. Fortunately, the Pro5000R calipers use a new drop-forging technique that has dramatically lowered the manufacturing cost and the resulting price of entry, bringing this incredible technology to the masses.

Radi-CAL = Massive Dynamic Stiffness Increase

Over the years, many different strategies have been employed to shrink the brake caliper footprint while maintaining adequate stiffness: More robust caliper bridge designs, two-piece calipers with steel through-bolts, exotic materials (i.e. Beryllium, MMC), forging rather than casting, monobloc design, etc. All of these innovations pushed calipers towards becoming lighter, smaller, and stiffer. However, until the advent of the Radi-CAL, the same basic rectangular, boxy shape remained the accepted standard.

Is a rectangular box really the most appropriate and efficient shape for a brake caliper? AP Racing has now proven that it is not. As a brake caliper clamps brake pads against a spinning disc, a tremendous tangential friction force occurs between the pads and the spinning disc. In other words, the caliper is pulled strongly in the direction of the spinning disc, as represented by the downward pointing arrow on the right side in Figure 1 below. The caliper resists that force via the spindle hard mounting points, depicted by the upward arrow on the left. The dynamic load placed on the caliper twists or pulls the caliper into a parallelogram shape.

Additional information

| Weight | 33.5 kg |

|---|---|

| Dimensions | 15 × 15 × 15 cm |